How Does an Automatic Transmission Work in a Car?

An automatic transmission is a complex system that allows a car to shift gears automatically without the need for driver intervention. This system provides a more comfortable and easier driving experience, especially in heavy traffic conditions. To understand how an automatic transmission works, it's essential to know its main components and how they interact with each other.

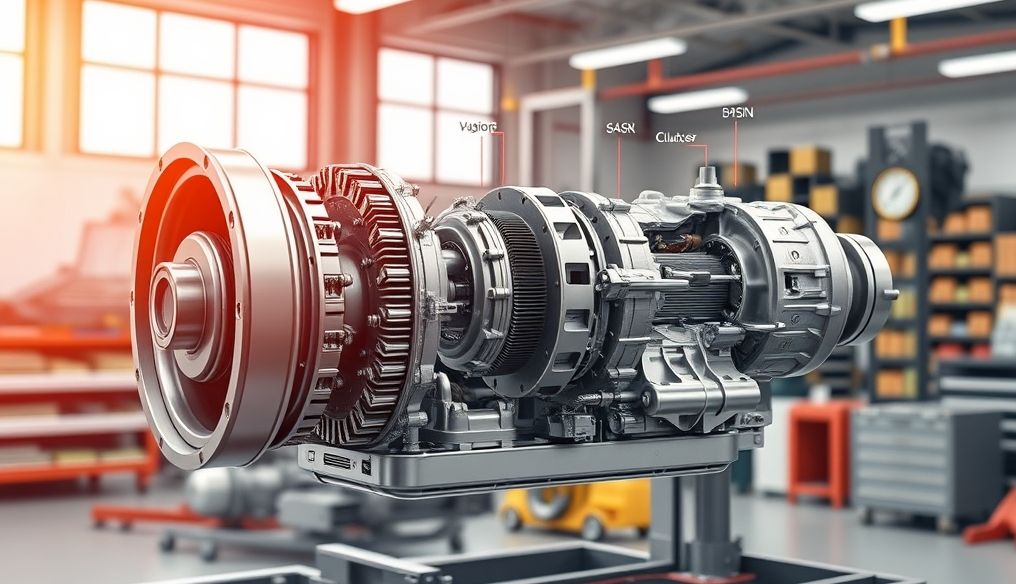

1. Main Components of an Automatic Transmission

An automatic transmission consists of several key components that work together to ensure smooth and efficient gear changes. These components include:

- Torque Converter: Connects the engine to the transmission and transfers rotational energy.

- Planetary Gear Sets: Consist of multiple gears that allow for different gear ratios.

- Clutches and Brakes: Used to control the planetary gear sets and change gear ratios.

- Valve Body: Controls the flow of transmission fluid to the clutches and brakes.

- Oil Pump: Provides the hydraulic pressure needed to operate the clutches and brakes.

- Electronic Control Unit (ECU): Monitors and controls the gear shifting process based on various inputs.

2. Torque Converter: The Heart of the Automatic Transmission

The torque converter is the component that connects the engine to the transmission, transferring rotational energy from the engine to the transmission. It operates using transmission fluid to transfer power, providing a flexible connection between the engine and transmission.

How Does a Torque Converter Work?

- Pump: Rotates with the engine and propels the transmission fluid.

- Turbine: Receives the transmission fluid from the pump and begins to rotate, transferring energy to the transmission.

- Stator: Located between the pump and turbine, redirects the transmission fluid to increase the efficiency of energy transfer.

The torque converter allows the car to idle without stalling, as the engine can continue to rotate while the turbine remains stationary. It also provides torque amplification at low speeds, helping the car accelerate faster.

3. Planetary Gear Sets: The Key to Changing Gear Ratios

Planetary gear sets are complex arrangements of gears that allow the transmission to change gear ratios. These sets consist of:

- Sun Gear: The central gear.

- Planet Gears: Rotate around the sun gear.

- Planet Carrier: Holds the planet gears.

- Ring Gear: Surrounds the planet gears.

By holding or rotating different parts of the planetary gear set, the gear ratio can be changed. For example, if the ring gear is held stationary and the sun gear is rotated, the planet gears will rotate and produce a specific gear ratio. Similarly, if the planet carrier is held stationary and the sun gear is rotated, a different gear ratio will be produced.

4. Clutches and Brakes: Controlling the Planetary Gears

Clutches and brakes are the components that control the operation of the planetary gear sets. Clutches are used to engage different parts of the planetary gear set, while brakes are used to hold certain parts stationary. By controlling the clutches and brakes, the gear ratio can be changed.

How Do Clutches and Brakes Work?

Clutches and brakes use hydraulic oil pressure to activate. When oil pressure is applied to a clutch, it engages two parts of the planetary gear set together. When oil pressure is applied to a brake, it holds a specific part of the planetary gear set stationary.

5. Valve Body: The Hydraulic Control Center

The valve body is the hydraulic control center of the automatic transmission. It controls the flow of transmission fluid to the clutches and brakes, allowing for gear ratio changes. The valve body consists of a series of valves and channels that direct the flow of fluid based on various inputs.

How Does the Valve Body Work?

The valve body receives inputs from several sources, including:

- Throttle Position Sensor (TPS): Provides information about how much the accelerator pedal is pressed.

- Vehicle Speed Sensor (VSS): Provides information about the speed of the vehicle.

- Electronic Control Unit (ECU): Sends signals to the valve body based on complex algorithms.

Based on these inputs, the valve body directs transmission fluid to the appropriate clutches and brakes to change gears.

6. Oil Pump: Providing Hydraulic Pressure

The oil pump is responsible for providing the hydraulic pressure needed to operate the clutches and brakes in the automatic transmission. The oil pump rotates with the engine and pumps transmission fluid through the transmission system.

Types of Oil Pumps:

- Gear Pump: Uses gears to pump the fluid.

- Vane Pump: Uses vanes to pump the fluid.

The oil pump must be able to provide enough pressure to operate the clutches and brakes correctly. If the oil pressure is too low, the transmission may not be able to shift gears properly.

7. Electronic Control Unit (ECU): The Brains of the Gear Shifting Process

The Electronic Control Unit (ECU) is the brains of the gear-shifting process in the automatic transmission. The ECU monitors many inputs, such as vehicle speed, throttle position, and engine load, and uses this information to determine when and how to shift gears.

How Does the ECU Work?

- Data Collection: The ECU collects data from various sensors in the car.

- Data Analysis: The ECU analyzes the data to determine the best gear ratio for the current conditions.

- Signal Transmission: The ECU sends signals to the valve body to activate the appropriate clutches and brakes to shift gears.

The ECU allows the automatic transmission to adapt to different driving styles and optimize fuel efficiency.

8. Transmission Fluid: The Lifeblood of the Automatic Transmission

Transmission fluid is a specialized fluid used in the automatic transmission to lubricate and cool the internal components. Transmission fluid plays a vital role in ensuring that the transmission operates smoothly and efficiently. It should be changed regularly to maintain the transmission's performance and prevent damage.

Functions of Transmission Fluid:

- Lubrication: Reduces friction between moving components.

- Cooling: Absorbs heat generated by friction.

- Power Transmission: Used in the torque converter to transfer power.

- Cleaning: Removes impurities and deposits.

9. Regular Maintenance of the Automatic Transmission

To ensure that the automatic transmission operates correctly and lasts a long time, regular maintenance should be performed. Regular maintenance includes:

- Changing Transmission Fluid: The transmission fluid should be changed according to the maintenance schedule recommended by the manufacturer.

- Checking Fluid Level: The fluid level should be checked regularly and ensured that it is within the correct range.

- Checking for Leaks: The transmission should be checked for any fluid leaks.

- Checking Filters: The fluid filters should be checked and cleaned or replaced as needed.

10. Common Problems in Automatic Transmissions and How to Handle Them

Although the automatic transmission is designed to be reliable, it may experience some problems over time. Some common problems include:

- Delayed Gear Shifting: May be caused by low fluid level or damage to the valve body.

- Jerking During Gear Shifts: May be caused by damage to the clutches or brakes.

- Fluid Leaks: May be caused by damage to seals or gaskets.

- Inability to Shift Gears: May be caused by damage to the ECU or valve body.

If you experience any of these problems, it is best to consult a qualified mechanic to diagnose the problem and repair it correctly.

In conclusion, the automatic transmission is a complex but essential system for smooth and easy car operation. By understanding the main components and how they work, you can keep your transmission in good condition and avoid costly problems.